Chongqing Degold Machine Co., Ltd.

Since its establishment in 1995, Chongqing Degold Machine Co., Ltd.

Has always endeavored to develop grinding and mixing technique in

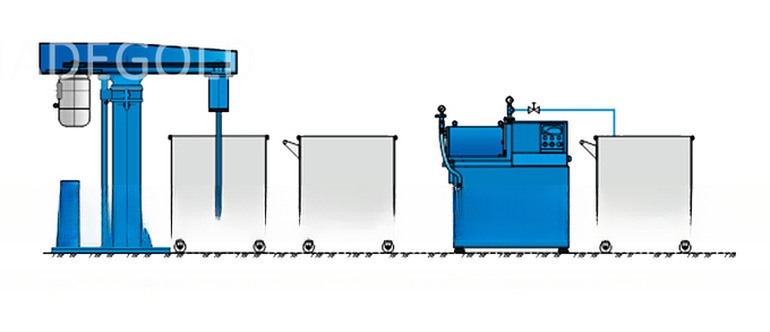

chemical industry. Now we have developed various models Horizontal

Bead Mills and Dispersers to fulfill industrial production needs

ranging from paints, inks, pharmaceuticals, food, dyes, cosmetics,

petrochemicals, and non-mental mines.

All Degold technical experts have been in this field since 80s in

the 20th century. We produce strictly as the requirements of

ISO9001: 2008 Quality System and CE standards. Degold designs,

develops, constructs, and installs production lines and advises,

trains customers.

Machines are popular in domestic and oversea market. We have

cooperated with so many famous painting and powder coating

manufactures such as Akzo Nobel, 3M, Clariant, and Sherwin-Williams

Co., Ltd. etc.

From 2007, we have begun to service oversea customers directly. Our

machines have been exported to many countries and regions such as

Australia, Argentina, Belgium, Brazil, Colombia, Chile, Indonesia,

India, Iran, Malaysia, New Zealand, Peru, Paraguay, Pakistan,

Poland, Singapore, South Africa, Spain, Tunisia, Thailand, Uruguay,

Vietnam etc.